The deck

The J105 helm, instrument remote and the propane bottle locker

The J-105 genoa tracks and the triple cabin-top rope clutches

|

Larry is smiling at the helm and our mascot is flying; Screwpile 2003. Notice instrument remote on the wheel and the propane bottle locker

![]()

The mainsheet system

| Over

the history of the J105 production, there has been several variations and

improvements for the mainsheet system within the same basic parameters (6:1

gross trim and 4:1 fine trim giving a combined 24:1 trim). A few years back,

the double ended plate was introduced by Andy Skibo with the swivel for the gross trim at

one end and the one for the fine tune at the other end. A discussion on the

web forum (below) contributed in making the change class-legal and soon

thereafter, the newer J/105s adopted the design.

Some J/105s have set up the gross trim aft to facilitate main trimming by the helmsman. On Chantecler, I have set up the fine trim aft because that is the one I am most likely to adjust when helming. Furthermore, when single handling Chantecler, I can easily adjust the gross trim because of the wide rotation angle of the forward swivel. Finally, when racing, the main trimmer should be forward of the traveler and thus the forward position for the gross trim is the most natural one. |

Forum discussion; from: http://www.j105.org/~oldforum/discus/messages/123/255.html?992986735#POST619

| Nelson Weiderman Wickford RI

Posted on Wednesday, January 03, 2001 - 9:51 am: |

Submission

#11 Revise 5.3.6: A fine tune system for the mainsheet with a maximum 24:1 power ratio may be installed over the coarse tune block or on a bracket mounted on the opposite side of the traveler at the same height as the traveler. Discussion: The revision to the fine tune system was proposed as a simply way to alter the existing system to minimize the problem of the fine tune sheet getting tangled in the mainsheet. |

| Marv Pozefsky - Bridgeport

Posted on Monday, March 26, 2001 - 6:07 pm: |

Has anyone tried, or planning to try the newly approved mainsheet-fine tune configuration. |

| John Kircher, Annapolis

Posted on Monday, March 26, 2001 - 7:08 pm: |

I trimmed

main on Bill Sutton's Blonde Attack several years ago both before and

after he 180-ed the mainsheet support plate. Not only does it reduce the

tendency for the two sheets to foul, it lets the main trimmer go forward

and to the rail with the coarse-tune, while leaving the fine-tune aft in

easy reach of the helmsman. Funny you should ask now, since we just turned Jay Boat's mainsheeting system around yesterday. |

| Marv Pozefsky -Bridgeport

Posted on Tuesday, March 27, 2001 - 5:27 am: |

John....Could you share your experience - what parts did you buy, where did you get them, did you double support and etc. Thanks |

| Nelson Weiderman KIMA Wickford RI

Posted on Tuesday, March 27, 2001 - 7:54 am: |

Marv,

here's my experience. I had a friend make up a single aluminum plate

with a mirror image on either side of the traveller. You can actually

work aluminum with woodworking tools. But later I noticed that Layline

carries a "swivel base flat bracket" that might work well in conjunction

with the existing platform. You would need longer bolts through the

traveller to attach both platforms. You would probably have to take off

the traveller, which could be a pain. The flat bracket is LL1005 on page

15 of the 2000 catalog and costs $30. I bought two Harken bases for the fine tune and eventually sent them both back. The 1573 fits the larger mid-range 1566 fiddle w/Hexaratchet, not our smaller 060. The 010 ball and socket base works, but you need a smaller clevis to fit the 060 and the working load is a little skimpy. I ended up using a hefty Shaefer eyestrap with standup spring. Works great. Use a padeye if you want even more heft. For the main block, I'm sticking with the 170 Hexa-Cat base. The bracket on top is no longer functional, but it shouldn't get in the way. I guess you can hacksaw it off if you like or tape up the integral clevis on top. If your mainsheet block needs to be replaced anyway, I think it is the 009 Hexaratchet is what you would need. Take this all with a grain of salt since it hasn't been tried out yet, but you can do the job for under $50 with no new blocks to buy. Note that I did not go with an additional support post and don't think one is necessary. With the split system, you have equal and opposite forces pulling up on either side of the traveller which lessens the need for a second support post. |

|

Jaffar Bentchikou - Annapolis Posted on Tuesday, March 27, 2001 - 8:36 am: |

Marv, I am

John's partner on Jay Boat. The job was done by team member Paul

Hillier, who is a marine industry pro. He used screwdrivers, a socket

wrench, a caulk gun with Sikaflex, a big piece of wood and the knowledge

to apply force when needed and where needed. The V-shaped aluminum

support is bolted to the bottom of the traveler's track. The aluminum

pipe support is attached to it with one screw and to the cockpit floor

with another screw. The geometry is easy because everything is

symmetrical. You turn the plate around 180 degrees, make a new hole in

the cockpit's floor for the screw at the bottom of the pipe and plug the

old hole. The problem is that on our boat they did not come apart easily

because the aluminum support plate became welded to the track's alloy

due to the galvanic current between the two different metals. They

should have been electrically insolated, but were not. For the new

installation he used Sikaflex. So, he used the piece of wood first to

knock the pipe support sideways and then to separate the V-shaped plate

from the traveler's track, with the help of large flathead screwdriver

driving a wedge in between. I know that properly plugging the hole left behind on the floor is critical. Until we test on the water, we have temporarily used a flat head machine screw with two washers and a good dose of Sikaflex. |

| Doug Berman/San Francisco

Posted on Sunday, April 01, 2001 - 10:37 am: |

I just got

Out-of-Options back from Key West/Miami and had my boat yard move the

course tune forward of the traveler. I opted to have them move the metal

triangle base forward and not fabricate a new one. I don’t know how difficult it was to remove, but the rigger did mention the metal post on my boat needed to be shortened once forward of the traveler.?. The other issue was the bottom bolt that holds the post to the deck, seized. He needed to drill out the bolt and run new threads (tap and dye). The filled the old hole (where the post was) with gelcoat and painted to match. It took him half a day to do. Yesterday, we participated in the Lightship, a 25-mile offshore regatta. I’m very happy my main trimmer is no longer sitting right next to me and is a good 3+ feet forward. He likes the arrangement as well, except when is lost his footing on that 12’ wave and fell in the cockpit. Details, details…. I just have to mention this... When we finally rounded the weather mark, it was blowing about 24 gusting to 33. We opted NOT to set the kite and run back with main and jib alone. About a quarter of the way back… Down a really big wave… With a really big gust… Boat speed was 23.5 knots! YEHAAA! Unbelievable experience. |

| Andy Skibo Plum Crazy Hull #90

Posted on Sunday, April 01, 2001 - 2:05 pm: |

To All: As

one of the originators of the now-allowed fine tune, Plum Crazy offers a

simplifying suggestion. If you are splitting the fine tune/coarse tune,

you don't even need the post that holds the plate. Plum removed it four

years ago, w/o a problem, and Plum certainly is a hard used boat. With

the new arrangement, the load on the new plate under the traveler is

balanced. You have one mainsheet fall to the swivel on one end, (four

falls to the fiddle block on the traveler itself) and one fall going

through the fine tune to the other end of the plate. In the old

arrangement, you had two falls going to one end of the plate, resulting

in a torque load trying to twist the traveler channel. The post was put

there by factory to support this unbalanced load. Not true any longer,

with split system. (And for reference, since we couldn't find our old

post, we sailed all of 2000 with the unbalanced arrangement w/o the post

with no problems.) So installation is really trivial. Just get a mirror-image plate made up (cut out of aluminum stock with hand tools), put a small bail on the end. Drill hole pattern to fit current swivel on other end. Disconnect fine tune from top of swivel/coarse tune assembly, complete with its spring, and just re-shackle to the small bail on other end of plate. Attach coarse tune swivel to the other end. Once you have the aluminum plate and the small bail, this takes less than 10 minutes to do. Patch hole in bottom of cockpit floor by using a large ss backing plate/washer, drilled for same bolt pattern that held post in place. Seal everything up with sealant, bolt down, and presto, you're done. (We left a bail there, so that when the J/35 fine tune to cockpit floor, double ended arrangement, is eventually approved, we can hook it back up again.) If you've got the aluminum stock available, and you cut it yourself, this whole thing costs less than $10 to do. We've installed it/removed it several times as rules have come/gone/come (locally/nationally) allowing use of this arrangement. It's not hard, it's cheap, and the improvement in tangle free use of fine tune is dramatic. |

| Tom Rolfes/Cincinnati-Southwest Harbor/ME

Posted on Sunday, April 01, 2001 - 11:00 pm: |

Andy/Nelson: As my boat is still 1150 miles away in Maine, I'll not get a chance to work on this aspect for a number of weeks yet. So, to get materials ready, do you have an idea of how thick an aluminum plate we will need? Has anyone a full sized sketch that could be downloaded or faxed? Tom Rolfes/Sidewinder #161 |

| Marvin Pozefsky

Posted on Monday, April 02, 2001 - 9:08 pm: |

Tom I have taken the existing plate off my boat and have brought it to a machine shop. They will send me the blueprint for the new part, the material list and etc. I will post them on the web for all to have! If you will not have the time or energy to make your own part, E mail me so I can direct you to the machine shop. |

| Jaffar Bentchikou - Annapolis

Posted on Tuesday, April 03, 2001 - 9:15 pm: |

Andy, I could very well believe that splitting the fine tune aft and the coarse tune fore of the traveler reduces dramatically mainsheet tangles. But why the new aluminum plate? Could you put the small bail for the fine tune directly on the floor, using for that purpose the hole that the old post is leaving aft of the traveler? Is this basically what you describe as the 'J35 fine tune to the floor' (without the double-ended arrangement)? To be legal, the fine-tune system should be 'at the same height as the traveler' but this can be solved with a piece of cable between the bail and the fine-tune swivel. |

|

Andy Skibo Plum Crazy Hull #90 Posted on Wednesday, April 04, 2001 - 8:16 am: |

Jaffar:

We did indeed use a small bail on the floor for what everyone calls the "J/35" arrangement. The problem with using a wire or line to get the bottom of the fine tune at the same height of the traveler is two fold. First, (and biggest) limitation is that the bottom of the fine tune arrangement is the swivel block with cam cleat. That block/cam cleat arrangement requires a relatively solid mounting to work. Otherwise, it will be a PITA to get the line uncleated. Second, (and lesser consideration) is fact that if it isn't mounted to a plate (or bracket) under the traveler, you've got the possibility of fudging on just how high is the fine tune block off the floor. I wouldn't worry about it personally, but we're still dealing with a fleet that has some folks concerned about whether removing the old snuffer control line cam cleats on the side of the cabin (which haven't been used in OD racing for seven years) is legal or not. So don't assume that tying the line to the bail on the cockpit floor "same height as traveler" or not will be accepted as kosher by everyone. The more compelling argument for the plate (or bracket) is fact that you probably need it to make the setup work. |

Forum discussion from: http://www.j105.org/~oldforum/discus/messages/22/284.html#POST826

| David Frizell-Perth Amboy,NJ

Posted on Friday, April 20, 2001 - 11:46 am: |

Has anyone come up with a source for the aluminum piece needed to retrofit the fine tuner?? |

| Marv Pozefsky/Bridgeport, CT

Posted on Saturday, April 21, 2001 - 9:31 am: |

Dave The first plate is almost done. After it is installed and tested, you will be contacted and can then place on order. I am forwarding inquiries directly to the machine shop. |

| Marv Pozefsky/Bridgeport,CT

Posted on Tuesday, May 01, 2001 - 5:21 pm: |

I have

installed and tested the first plate. Works like a charm. Those who

contacted me will get an E mail from the machine shop. The price will be

$ 82.00 plus shipping. To order the fore and aft tuning plate Email

'Slingshot31998 at aol dot com' or Fax (203)878-4232 Dennis Dawid Dawid Manufacturing Inc. 185 Research Drive Milford, CT 06460 |

| guy ballou/#164, Dark Star, Annapolis

Posted on Wednesday, May 02, 2001 - 10:27 am: |

Marv, any change you could take a picture and put up on the webpage. guy |

| Nelson Weiderman KIMA Wickford RI

Posted on Tuesday, May 08, 2001 - 10:36 am: |

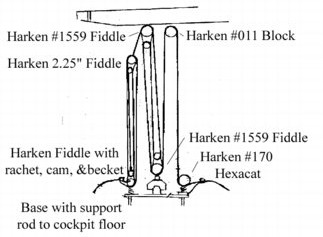

Here's a

photo of the modified fine tune from a boat that has the modification

installed (not KIMA). Note that the coarse tune block is the same as the

original, but with the "ears" clipped off. I did this on KIMA with a

hack saw and a file, so the only parts I bought were the eyestrap and

the spring, and the new aluminum (3/8") plate. Note also that this

installation does not use a support post. I recommend that you leave the

one that's there, but don't bother with a second support.

|

| Stuart Burnett/Richmond, VA #198 Legacy

Posted on Wednesday, May 09, 2001 - 10:28 pm: |

I've been trying to visualize how you do this and still get a fair lead using the existing blocks...so far with no success. Is it possible to set this up without having crossed lines going to the block on the traveler? Can someone explain or post a diagram? Thanks! |

|

Nelson Weiderman KIMA Wickford RI Posted on Thursday, May 10, 2001 - 7:07 am: |

Stuart, go to the Fleet #5 site and click on "Alternate Fine Tune Installation". The diagram there shows how it is done without having crossed lines.. |

| Stuart Burnett/Richmond, VA #198 Legacy

Posted on Thursday, May 10, 2001 - 1:53 pm: |

Has anyone sailed with this configuration extensively and what has been your experience. I can see the benefit of allowing the main trimmer to sit further forward (especially since mine weighs 240+), but what effect does it have on cockpit space? Now there's a pretty big projection forward into what used to be wide open cockpit. Also, has anyone sailed short-handed with this configuration? We have a fair amount of trouble with the traveler-mounted block twisting on jibes and occasional with the fine-trim block getting wrapped up in the course-trim cleat, is this configuration less susceptible to that or more? |

| Andy Skibo Plum Crazy Hull #90

Posted on Thursday, May 10, 2001 - 2:42 pm: |

Stuart:

The picture posted by Nelson is from Plum. We've been sailing with that setup for two years (except for a few races starting with last years' NAs through KW, when the system was temporarily not allowed), both in races as well as with two person deliveries. And before that, we sailed with essentially same set up, except fine tune falls run to small blocks directly on cockpit floor, for two preceding years. (You can still see eye strap for that in picture.) It's primary advantage, whether you have 6 people on the boat or 1, is fact that you never get the usual tangles, overlaps, rat's nest, between fine tune and coarse that you used to get with the factory setup. Especially on gybes. As far as the slight extra protrusion of one extra end of the plate, you'll never notice it. On a tiller boat, that slight protrusion sticks into the space the helmsman moves around in on tacks, etc. I had your same worry before we first installed it. Never noticed it. Never hit my shins on it. You'll find that you just don't put your body that close to the mainsheet falls/fine tune fall anyway, so you just don't get near the plate. And setup will not change the position of where your main trimmer sits, unless you choose to. Both lines still run to his hands together, as they did before. They just don't get tangled. Trust me, all you'll get is a heck of a lot easier handling of mainsheet/fine tune, with no observable difference in cockpit space. |

| Cedric Lewis MIRAGE HULL#328

Posted on Friday, May 11, 2001 - 1:38 pm: |

Stuart,

We have had our boat for exactly one year. We quickly discovered what a nightmare the main sheet/traveler can be. In light air it was a nuisance but in heavy air it can be down rite dangerous. We followed Andy's lead and split the fine tune and main sheet and had a custom plate fabricated to replace the existing plate. I took the existing plate, scored it along the traveler. I then removed the plate, traced it and then flipped it around (180 degrees) and traced it again making sure that the bottom line and the scored line matched. The end result is a diamond shaped plate that protrudes on either side of the traveler in a mirror image. I also traced the mounting holes and the post hole. There is no need for a second post as long as you use 3/8" stock for the plate. The whole mod cost me ~ $75. The only thing I had to buy in addition to the plate was the strap and the hardware to mount it to the plate. In addition to the easy of use it allows us to get the sails set after a tack and get the main trimmer on the rail. Now the helmsman (or driver as I guess they are now called) can make the final adjustments with the fine tune. |

| Bill Hunt/Rhapsody 487/Boothbay Harbor, ME

Posted on Friday, May 11, 2001 - 2:21 pm: |

Does the

plate that Dawid Mfg is offering match the one Andy has on Plum Crazy?

(i.e. same kind of nice finished curves, etc.) I have a 4 year old so I

am concerned that it not have sharp corners or edges (actually even w/o

the 4 yr old I'd have the same concern). Thanks. |

| Jonathan Udell NJ

Posted on Friday, May 11, 2001 - 4:43 pm: |

We made Andy's plate for him, so thanks for the nice comments. I also have in my hands five of Dawid Mfg's new plates, just arrived today. They are quite nicely made; predrilled and anodized. I think you will be very happy with their work. |

| Bill Hunt/Rhapsody #487/Boothbay Harbor, ME

Posted on Friday, May 18, 2001 - 9:25 pm: |

Here is a

picture of the Fine Tune double ended plate from Dawid Mfg. (see above).

|

| Andy Skibo Plum Crazy Hull #90

Posted on Tuesday, May 22, 2001 - 8:27 pm: |

To Tom and

others: I'm not sure why the David plate has swivel hole pattern in both

ends but worrying about a second swivel is unnecessarily complex (let

alone illegal). The fine tune block swivels around it's own post--just

as it does on the standard fine tune setup. The plate we used (and plate which I understand Layline will sell, complete with bail already attached) just had two holes drilled on the fine tune end for a bail. These plates are aluminum--a household drill bit and electric drill will go through them like butter. Once you have bail mounted, all you have to do is take standard fine tune block, and use small D shackle to pin it through the bail. Stand-up spring will hold it up, and will easily fit over the D shackle. You don't need a stand up post mounted to the plate. The bail works just fine. PS: You don't want to lose any of the throw available on this fine tune setup by using 10 inches of the vertical clearance for a swivel arm anyway--even if it were legal. |

| John Sullivan / San Francisco / Hull 181

Posted on Tuesday, June 26, 2001 - 12:07 am: |

Has anyone, including the TC, come up with a totally legal split mainsheet system diagram? I want to try it but want it to be legal. |

| Jim Snair/Andrea5 of Sunnybrook/#506/Halifax, NS

Posted on Tuesday, August 28, 2001 - 11:50 pm: |

FYI: New

Owners who are reviewing this thread...The fine tune/racing mainsheet

system is available as a factory option. Its being installed on at least three boats in the 501-506 range. |

| Nelson Weiderman #300 KIMA

Posted on Tuesday, October 02, 2001 - 5:23 pm: |

Here's a

diagram of how to rig the alternate fine tune system, courtesy of George

Petkovic of Fleet #5.

|

| Perry Moy / Hull #39 / Synergy

Posted on Friday, November 30, 2001 - 6:08 am: |

Some help in removing the old plate. I have hull #39 and I removed the four(4) bolts under the plate and the support post. The plate does not move. TPI suggests that I drill out the bolts; can not see that. So any suggestion will be a great help. |

| Nelson Weiderman / Hull #300 / Kima

Posted on Friday, November 30, 2001 - 8:11 am: |

A couple of years ago, I removed the plate on #37 to turn it around. I had the same problem as you have. As I recall, I just had the courage to use more and more "persuasion". I'm not sure whether it was in the form of a small sledge or in the form of a wedge between the plate and the traveller. The two obviously weld together from galvanic action, but the "weld" is not as strong as the plate or the traveller and you are going to break the weld before you break either the two pieces being held together. No guarantees, mind you, but drilling out the bolts seems much harder in my mind and does not break the weld anyway. You might also try softening it up with Liquid Wrench before applying the extra force. Let us know what finally works. |

| Jaffar Bentchikou / Hulls #208 & 536 / Annapolis

Posted on Friday, November 30, 2001 - 9:30 pm: |

I have had the same problem and it was solved by my team member Paul Hillier. Click on the link to find the post. He used a large screwdriver, a big piece of wood, a big blow and the knowledge to mix them together properly. However, on your hull the galvanic current has worked over a longer period and may have produced a stronger natural weld. I agree with Nelson that drilling may not be the proper solution, as you have already removed the four bolts and the natural weld is between the traveler and the plate. If you do not want to try a big blow, my son Chafik, who is a mechanical engineer, advises to try to heat the plate. As the two metals are different, they will expand at a different rate and thus apply stress on the natural weld. |

| John Sullivan / Hull 181 / Wianno / San Francisco

Posted on Friday, November 30, 2001 - 10:37 pm: |

I used the heat method and after about 4 cycles a little leverage with a big wrench removed the plate. It took some time but eventually it came off!!! |

![]()

Pulling the J105 mast forward on a run

Forum discussion from: http://www.j105.org/~oldforum/discus/messages/4/113.html?956093601#POST591

| Rich Levitt Hull 203 Maccabee

Posted on Thursday, August 26, 1999 - 6:27 pm: |

Anyone care to comment on the techique of pulling the mast forward when on a run? I know that it is fast. Boats equipted for PHRF racing often have a spare jib halyard which can be lead to the stem and used to pull the mast forward when using the spinnaker. The standard J-105 in one design mode does not have a second jib halyard as standard equiptment. Would it be class legal to to use or add a second jib halyard for this purpose? |

| John Driver Tech Comm Annapolis

Posted on Thursday, August 26, 1999 - 7:04 pm: |

Rich, A second jib halyard is not standard equipment for OOD racing and therefore it would NOT be considered class legal to pull your mast forward in this manner. |

| Alex Baluta 72-Highlander - Toronto

Posted on Friday, August 27, 1999 - 2:54 pm: |

Aside from the question of legality, can you explain in a bit more detail how and why this works? thanks. |

| Anon

Posted on Sunday, August 29, 1999 - 12:49 pm: |

Could we hear from the rest of the tech committee on this subject? I cannot fathom how this technique, standard practice in every form of racing there is, could be considered illegal. |

| Stuart Burnett - Richmond VA - 198 Legacy

Posted on Monday, August 30, 1999 - 12:28 pm: |

Though I'm not on the technical committee, I support John's position that installing and using a 2nd jib halyard for the purpose of adjusting mast rake in One Design races would not be consistent with the class rules. Besides, with raked spreaders and fairly tight rig tuning, how much can you move the mast forward anyway? Certainly you could not move the mast to a vertical position, which would require inverted bend which I think would risk a mast failure. |

| Geoff Moore

Posted on Tuesday, August 31, 1999 - 7:26 am: |

The whole

point of moving the mast forward downwind is simply to help hold the

main boom and mainsail out. Imagine your boat drifting in no wind.

Imagine your mast raked way aft. If you were to push the boom and

mainsail all the way out and then let go the boom and mainsail would

want to fall towards centerline. Now imagine the mast raked forward so

that it extended out over the bow. If your sail and boom were on

centerline they would want to fall all the way out. Every little bit you

can pull the mast forward while sailing downwind in light air means that

the wind will have an easier time inflating your mainsail. In heavy air

it serves almost no benefit. Most race boats drop their jibs downwind so if it is legal in their class they use the jib halyard to pull the mast forward. The J/105 does not allow for a second jib halyard, but the existing halyard is still attached to the bow of the boat of the boat through the luff of the rolled jib. You could pull the halyard up to accomplish the same thing. Be careful that you don’t damage the lighter material in the front of your jib! A little extra tension will be amplified when you pump up the back stay and pull the mast aft with mainsheet after you turn the leeward mark. It is common to ruin the shape of a new sail by over tensioning the luff. Geoff Moore New J/105 partner (March delivery) Shore Sails Ltd. 401-849-7700 |

| Dave HaglerAnnapolis

Posted on Tuesday, August 31, 1999 - 3:34 pm: |

There was

at least one J105 that has (in the past) used this technique downwind.

When we sailed on a J29 we always put the old jib halyard on the tack

shackle in the bow and cranked the mast forward. It is VERY important

(IMHO as just a crew member) that is issue be addressed by the technical

committee ASAP. The boat that has (in the past) used this technique is

very fast down wind. There may be other factors other than the halyard,

however, if this procedure/set up is deemed 'OK' we would be trying to

get a rig set up to do this before CBYRA RW. Please do not ask me what boat it was (not really important), it is more important to decide if it will be 'officially' considered legal. |

| Stuart Burnett - Richmond VA - 198 LEGACY

Posted on Tuesday, September 07, 1999 - 11:41 am: |

I've referred this thread to the full J/105 Technical Committee and asked them for an expedited ruling. |

|

Chris GroobeyJavaAnnapolis Posted on Tuesday, September 07, 1999 - 10:57 pm: |

Reply to

Geoff Moore: First, welcome to the fleet, Geoff. I used to enjoy your regular e-mails on tuning and sails and look forward to more posts now that you are an owner. You certainly educated me on why masts are moved forward downwind; I had assumed that it was to move the center of effort forward and/or to enlarge the slot. I've been thinking about your suggestion on how to bring the mast forward using the halyard of the furled jib and, to be honest, I'm having trouble imagining how it would work. Here's why: I think of the roller furling system as essentially being equivalent to a piece of rod rigging. The length of the rod is fixed, so the only way to change the distance between the ends of the rod is to bend or straighten the rod. If the goal downwind is to shorten the headstay length, then a second halyard does this by becoming the shorter of two headstays and inducing bend in the (longer) roller furling unit. But if the halyard of the furled jib is tightened in an attempt to bring the mast forward, doesn't the now-tight luff of the jib serve to keep the roller furler straight? In other words, does the tight luff become a shorter headstay than the roller furler, or does it actually reinforce the furler against lateral deflection? I hope others will chime in on this issue as the correct answer would also influence upwind trim, that is, the relationship between jib halyard tension and headstay tension in a boat without runners. |

| Jaffar Bentchikou - Jay Boat 208 - Annapolis

Posted on Thursday, September 09, 1999 - 5:37 pm: |

According

to Stuart Walker (a manual of sail trim, p88) quote 'forward rake

counteracts the windward yawing moment created by the offset mainsail

and the offset spinnaker. It determines the angle of incidence of the

head - the relationship between the horizontal surfaces of the spinnaker

and the air flowing above them. .. it separates the spinnaker from the

mainsail, greatly improving the efficiency of the partially blanketed

spinnaker. The aerodynamic lift created by the air flowing above the

spinnaker, the angle of incidence and the lift are increased by forward

rake' Unquote Thus, it seems to me that raking the mast forward would not benefit a J105 with a class asymetric spinnaker on a sprit as much as boats with symetrical spinnakers running deeper angles and subject to rocking and unstable oscillations of the chute in heavy air. So my vote goes in favor of NOT allowing in the class any additional halyard or mast raking. Somebody said in the discussion on 'Jib Tracks' that we needed to 'keep the boat simple'. I believe that this apply perfectly to mast raking with only minor benefits for us. We need however to draw the line higher on the benefit scale and keep looking for low cost hardware improvements which would have a greater impact on the quality of our racing and the speed of our learning. There is one device out there that fits that definition perfectly: 'jib lead cars that are adjustable under load'. All indicators point in the same direction: Jeff Johnstone in the other discussion was open to the idea 'if it improved class racing'. Most people who contributed to that discussion were in favor of it as well as many J105 owners I have talked to. So, please, please, Chris, get the issue of adjustable jib cars on the agenda of the technical committee. |

| Andy Skibo Plum Crazy Hull 90

Posted on Saturday, September 25, 1999 - 5:48 pm: |

Jaffar hit the reason you pull the mast forward. You are basically trying to get increased separation of kite and main when running deeper angles in light air. As air gets heavier, advantage disappears for a J/105. Chris asked if there was a way of using the single jib halyard in use for jib to do this. I haven't figured that one out. There is a way of achieving same result, without using second halyard (we've used this when too lazy to pull second halyard down, or when second halyard is stripped out of mast, with only messenger line in place.) And Chris came close to hitting the answer when he said only choice was to either "shorten the rod" or "bend the rod". Choice #2 is the answer. Just leave roller furler control line cleated (jib is furled, with a couple of turns of the jib sheets around the furled sail/forestay) and crank back a bit on both jib sheets. That pulls middle of forestay back, pulling masthead forward. And you don't have to move the forestay aft a lot, to move masthead foreward enough to achieve desired affect, due to geometry of angle of attack. A little more rigorous on furled jib. Makes no difference to forestay, since it has to deflect same amount regardless of whether you're pulling on it using jib sheets, or whether it is simply falling out of way, because you've pulled masthead forward with second halyard. This variant uses installed, class legal equipment only, and is trivial, takes seconds, to do. A standard racing technique. Hard to see how you'd define this variant as not acceptable. Either variant works equally well. And, with newer kites which run much deeper downwind than original designs, the technique is more effective now (in light air) than it would have been for older design kite. Neither technique is necessary in heavy or even medium air. |

| Nelson Weiderman Wickford RI

Posted on Tuesday, April 18, 2000 - 10:48 am: |

Just to close out this thread with some definitive information, the ruling from the TC on using a jib halyard to rake the mast forward was NO, it is NOT allowed. The reason was that most boats don't have 2nd halyards; and in order to take advantage you'd probably have to have an illegally long backstay throw on the cylinder. |

| Jonathan Udell NJ

Posted on Tuesday, April 18, 2000 - 12:31 pm: |

Nelson,

I've just reviewed the Technical Committee rulings as presented in the J105 Class website and there is nothing whatsoever with regard to halyards pulling rigs forward. Please clarify where this exists per your latest entry. |

| Nelson Weiderman Wickford RI

Posted on Tuesday, April 18, 2000 - 4:33 pm: |

Jonathan, you're right. It's not there. When I created the new page on interpretations, I recalled this discussion about raking the mast and could not find an interpretation. When I asked, I learned that there are some questions that are answered by the TC directly and never reach the level of a formal Rule Interpretation that is circulated to the Executive Committee. I posted it here because I thought people would look here for an answer to the question that was raised in this thread. Now that I've done so, I'm sure that some people will suggest that it deserves the status of a formal interpretation. I guess I would tend to agree. Jeff??? |

![]()